Fenomer casting systems

Fenomer systems are filled/unfilled, solvent-free potting compounds or casting systems based on PUR chemistry.

The liquid starting components (polyol and isocyanate) are mixed statically or dynamically on 2-component metering machines and poured. The corresponding reaction compounds cure after a pot life that can be set according to customer specifications. This allows an exact adaptation or extension of the manufacturing cycles of our customers. Thanks to their very high temperature and chemical resistance (liquids and gases), Fenomer systems are used especially for the bonding or direct demolding of filter end plates. Fenomer casting systems are also recommended for the production of (rubber-like) elastic molded elements. The surface hardness can be varied in the Shore A to Shore D range, depending on the application and customer requirements.

Fields of application

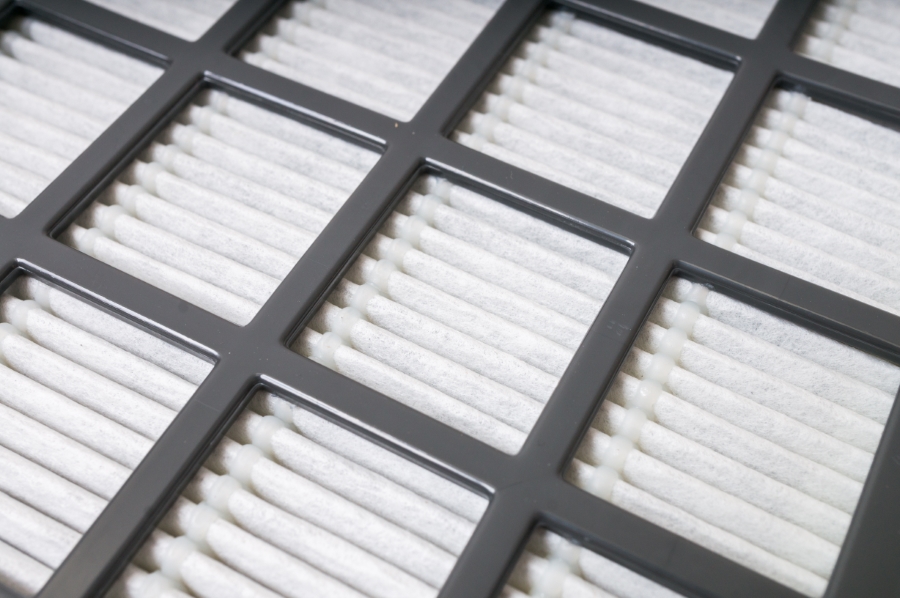

- Filter end plates (oil filters, diesel filters and air filters)

- Filter flanges in the industrial air filter sector

- Filter housings

- Potting/gluing of various materials

Etc.

Properties and Benefits

- Broadly adjustable pot life

- High temperature and chemical resistance

- Variable Shore hardness

- Filled or unfilled versions

Your application is not listed, but you have an idea or already a running production/application?

Please do not hesitate to contact us!

Together we will find an optimal and sustainable solution for your needs. From basic system formulation, adaptions, to support after production launch.

We are happy to offer you our comprehensive support.